The minerals consisting of silver element are mainly divided to silver-gold minerals and lead-zinc-copper associated minerals. The sliver productivity from these minerals per year is about 99% of the total amount.

Productivity: 0.18-7 (m³/min)

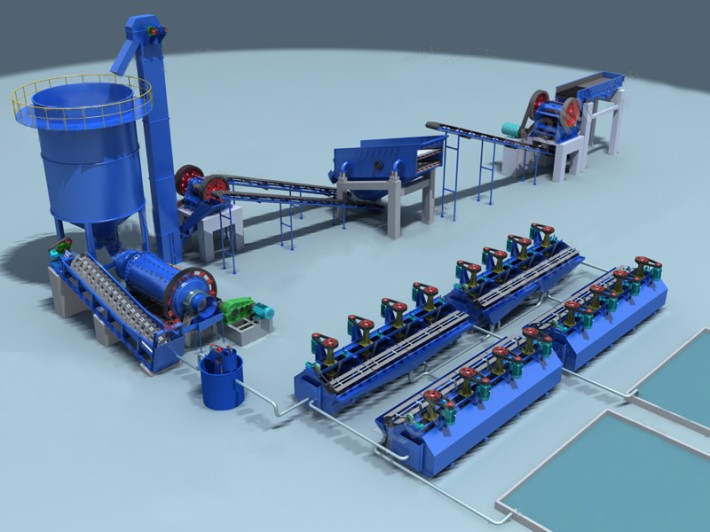

Application: Ore concentrate/separator plant

Main Equipment: Jaw crusher, impact crusher, cone crusher, ball mill, tube mill, magnetic separator, mine flotation machine, drum screen, high frequency screen, etc.

The minerals consisting of silver element are mainly divided to silver-gold minerals and lead-zinc-copper associated minerals. The sliver productivity from these minerals per year is about 99% of the total amount. The silver ore beneficiation plant or the silver ore separation process or the silver ore processing line is made up of jaw crusher, hammer crusher, dry-wet ball mill, ceramics ball mill, magnetic separator, flotation separator, spiral classifier, drum sieve, high frequency screen, chute feeder, rotary dryer, and mixer, etc.

Our company, as one of the most advanced silver ore separation plant manufacturer in China, has developed two high efficient methods for the silver ore processing: the flotation separation method and the cyanide processing method. Which method should we adopt is based on the composition of the minerals consisting of silver ore. When the minerals mostly consist of argentite and native silver, both the flotation separation and the cyanide processing method are advisable. When there is too much pyrargyrite, proustite and selenium silver remaining in the minerals, we can just adopt the flotation silver ore beneficiation plant.

Henan Fote Heavy Machinery Co., ltd. is a large-scale and professional manufacturer of mining machinery and general machinery. With continuing development in the international market, the sales network of products produced by Fote Machinery has been steadily expanded, and products produced by Fote Machinery have been sold to more than 90 countries and regions all over the world, such as Russia, United States, Kazakhstan, India, Indonesia, South Africa, Libya, Sudan, Iran and so on.

Leave us a message for more details and price list?

The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite.

Production process: Storage bin—feeder—jaw crusher—jaw fine crusher—ball mill—spiral classifier—magnetic separator(fine powder). These machines are all connected by the belt conveyors.

The flotation separation process also known as the flotation separating production line realizes the mineral particle separation based on the working principle of different physical and chemical properties of the minerals leading to different floatability.

Technological characteristics: high efficiency, low energy consumption, great handling capacity, economical performance and wide range of application

Henan Fote Heavy Machinery Co., Ltd.,the former Henan First Machinery Factory,founded in Henan Zhengzhou- China machinery manufacturing capital in 1982,is a large joint-stock company specialized in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an area of 240,000 m², more than 2000 existing employees, 160,000 m² standardized....

Read MoreAddress: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China