The manganese ore beneficiation plant, also named manganese ore separation process or manganese ore processing line, is divided to the flotation manganese ore beneficiation plant and the magnetic manganese ore separation plant.

Productivity: 0.18-7 (m³/min)

Application: Ore concentrate/separator plant

Main Equipment: Jaw crusher, impact crusher, hammer crusher, vibrating screen, classifier, ball mill, etc.

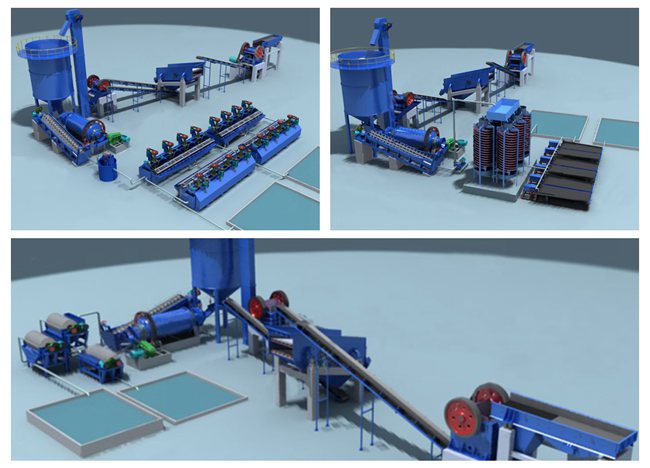

The manganese ore beneficiation plant, also named manganese ore separation process or manganese ore processing line, is divided to the flotation manganese ore beneficiation plant and the magnetic manganese ore separation plant. The complete plant featuring high efficiency, low energy consumption and little investment will use the following machines: jaw crusher or hammer crusher, ball mill, classifier, magnetic separator, flotation separator, concentrator, dryer, feeder, elevator and belt conveyor.

The intensity magnetic separation is a main processing method in the manganese ore beneficiation plant. Because of the much investment and low handling capacity for single equipment, for the large scale ore beneficiation plant, this method or the manganese ore intensity magnetic separator usually works as the auxiliary method, not the core beneficiation one. The manganese ore beneficiation plant is able to process manganese carbonate ore and manganese oxide ore etc. For the water-deficient area and small scale production, we often use the dry type ore beneficiation method; or we will adopt the intensity magnetic separation method.

Henan Fote Heavy Machinery Co,. Ltd. is a large joint-stock corporation, majoring in heavy mining machinery and civil machinery manufacturing. Fote occupies an area of 360,000 square meters, including 60,000 square meters of standard heavy industrial workshops equipped with over 500 large and medium-sized metal processing, riveting and assembly equipment. Total online staff of Fote Heavy Machinery is more than 2,000.

For more details, please leave us a message by filling the form below, thank you!

The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite.

Production process: Storage bin—feeder—jaw crusher—jaw fine crusher—ball mill—spiral classifier—magnetic separator(fine powder). These machines are all connected by the belt conveyors.

The flotation separation process also known as the flotation separating production line realizes the mineral particle separation based on the working principle of different physical and chemical properties of the minerals leading to different floatability.

Technological characteristics: high efficiency, low energy consumption, great handling capacity, economical performance and wide range of application

Henan Fote Heavy Machinery Co., Ltd.,the former Henan First Machinery Factory,founded in Henan Zhengzhou- China machinery manufacturing capital in 1982,is a large joint-stock company specialized in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an area of 240,000 m², more than 2000 existing employees, 160,000 m² standardized....

Read MoreAddress: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China