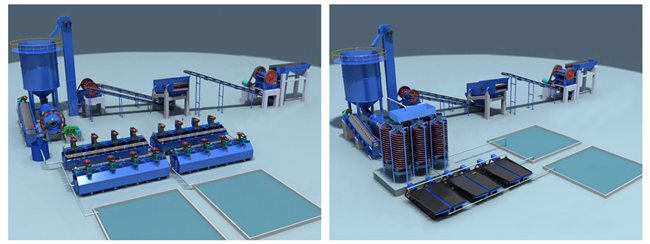

The gold ore beneficiation plant or gold ore processing plant is made up of jaw crusher, ball mill, classifier, flotation separator, adsorption tank, concentrator, dryer, feeder, elevator and conveyor etc.

Productivity: 0.18-7 (m³/min)

Application: Ore concentrate/separator plant

Main Equipment:Jaw crusher, impact crusher, hammer crusher, flotation machine, classifier, ball mill, concentrator, etc.

The gold ore beneficiation plant or the gold ore processing line is made up of jaw crusher, ball mill, classifier, flotation separator, adsorption tank, concentrator, dryer, feeder, elevator and conveyor etc. Our company is regarded as the advanced gold ore separation plant manufacturer in China and our plant has advantages of high efficiency, low energy consumption, high handling capacity and low cost.

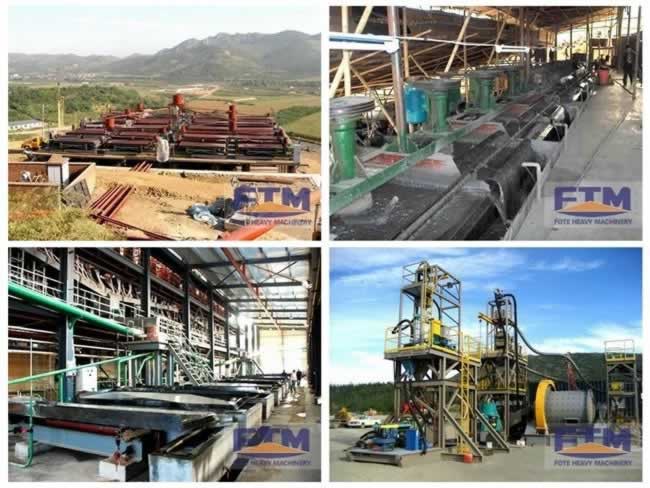

The gold ore beneficiation plant of our company is divided to tom types: the flotation gold ore beneficiation plant and the gravity gold ore separation process. Our gold ore processing line experts have spent years in doing research and development on the latest physical gold ore beneficiation technology by introducing the advanced international research result. We realize the non-pollution gold production without adding the chemical agent. The promotion of gravity gold ore separation process technology can not only help to save much human labor, but also to improve the environment. The non-chemical processing method also saves much cost for the gold ore industry.

Henan Fote Heavy Machinery Co., ltd. is a large-scale and professional flotation gold ore beneficiation plant, gravity gold ore separation process, gold ore processing line and gold ore separation plant manufacturer, with two professional industrial workshops and more than 300 machine machining, welding and assembly equipment with large and medium size. Fote Machinery has won wide praise at home and abroad by the exquisite techniques and advanced technology, and it’s also become the large mining machinery export base in China.

Leave us a message for more product details and price list?

The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite.

Production process: Storage bin—feeder—jaw crusher—jaw fine crusher—ball mill—spiral classifier—magnetic separator(fine powder). These machines are all connected by the belt conveyors.

The flotation separation process also known as the flotation separating production line realizes the mineral particle separation based on the working principle of different physical and chemical properties of the minerals leading to different floatability.

Technological characteristics: high efficiency, low energy consumption, great handling capacity, economical performance and wide range of application

Henan Fote Heavy Machinery Co., Ltd.,the former Henan First Machinery Factory,founded in Henan Zhengzhou- China machinery manufacturing capital in 1982,is a large joint-stock company specialized in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an area of 240,000 m², more than 2000 existing employees, 160,000 m² standardized....

Read MoreAddress: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China