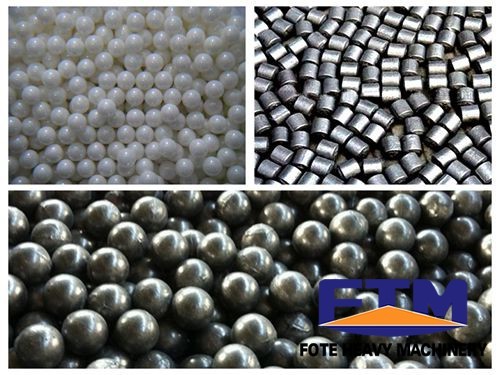

Generally, ball mill accessories include durable steel ball, steel forging, high alumina ball, ceramic ball, ball mill plate and so on. The following mainly introduces the most used ball mill plate, durable ball mill and steel forging.

Generally, ball mill accessories include durable steel ball, steel forging, high alumina ball, ceramic ball, ball mill plate and so on. The following mainly introduces the most used ball mill plate, durable ball mill and steel forging.

Medium alloy steel has gradually taken the place of manganese steel and other plates and become the trend. In recent years, the size of the ball mill has been uniformed—the width is 314mm, the length of the whole plate is 500mm, half of the plate is 250mm long, the thickness is 40-50mm and the volume is 45-55kg.

Steel ball and ball mill cylpebs is a kind of ball-type durable iron alloy product generated by the forging, spinning, casting and rolling. Carbon, chromium, manganese, molybdenum and other metals are the main additive elements. They are the most important of today’s crushing industry and bearing industry. And they are widely used in electric power, building materials, mining, metallurgy and other fields.

Henan Fort specialized in mining machinery production for more than 30 years and is China's largest mining machinery production and export base. The main products are ball mill and its accessories, crusher, grinding machine, ball press machine and other equipment. Welcome the world-wide customers take a visit!

The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite.

Production process: Storage bin—feeder—jaw crusher—jaw fine crusher—ball mill—spiral classifier—magnetic separator(fine powder). These machines are all connected by the belt conveyors.

The flotation separation process also known as the flotation separating production line realizes the mineral particle separation based on the working principle of different physical and chemical properties of the minerals leading to different floatability.

Technological characteristics: high efficiency, low energy consumption, great handling capacity, economical performance and wide range of application

Henan Fote Heavy Machinery Co., Ltd.,the former Henan First Machinery Factory,founded in Henan Zhengzhou- China machinery manufacturing capital in 1982,is a large joint-stock company specialized in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an area of 240,000 m², more than 2000 existing employees, 160,000 m² standardized....

Read MoreAddress: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China